Description

Rubber process oil is a type of specialized base oil that is used in the production of rubber and rubber products. It is used as a processing aid, which means that it is added to rubber compounds to improve their processability during manufacturing.

Rubber process oil is a complex mixture of hydrocarbons that are derived from the refining of crude oil. It contains a combination of aromatic, naphthenic, and paraffinic compounds, which gives it a unique set of properties that make it suitable for use in the rubber industry.

One of the main functions of rubber process oil is to reduce the viscosity of rubber compounds, which makes them easier to process and shape during manufacturing. It also helps to improve the dispersion of fillers and other additives in the rubber compound, which can improve the overall performance of the finished product.

Rubber process oil is also used to improve the physical properties of rubber products. It can improve the flexibility, elongation, and tear strength of rubber compounds, making them more durable and resistant to wear and tear. Additionally, rubber process oil can help to reduce the cost of production by allowing manufacturers to use lower-cost raw materials without sacrificing the performance of the finished product.

Rubber process oil is a specialized type of base oil that is primarily used in the manufacturing of rubber and rubber products. It is used as a processing aid, which means that it is added to rubber compounds to improve their processability during manufacturing. Here are some of the common applications of rubber process oil:

Usages

1. Tire manufacturing: Rubber process oil is widely used in the production of tires. It is added to the rubber compound to improve its processability and help ensure that it can be easily shaped into the desired tire shape. Rubber process oil also helps to improve the physical properties of the tire, such as its flexibility, durability, and resistance to wear and tear.

2. Industrial rubber products: Rubber process oil is used in the manufacturing of a wide range of industrial rubber products, including hoses, belts, gaskets, seals, and other components. It is added to the rubber compound to improve its processability and to enhance its physical properties, such as its flexibility, strength, and resistance to environmental factors.

3. Automotive components: Rubber process oil is used in the production of various automotive components, including engine mounts, seals, gaskets, and other rubber components. It is added to the rubber compound to improve its processability and to enhance its performance in high-temperature and high-pressure environments.

4. Adhesives and coatings: Rubber process oil is used in the production of adhesives and coatings. It can help to improve the adhesion properties of the adhesive or coating and make it more flexible and durable.

5. Other applications: Rubber process oil is also used in the production of various other products, such as shoe soles, wire and cable insulation, and molded products. It is used to improve the processability and physical properties of the rubber compound, making it easier to work with and more durable. Overall, rubber process oil is an essential component in the production of rubber and rubber products. Its unique properties make it an ideal processing aid for rubber compounds, and ongoing research and development are focused on improving its performance and sustainability to meet the evolving needs of the industry.

Applications:

- Automobile Tires

- Rubber shock absorbers

- Footwear

- Industrial Hoses

- Wire and cable coverings,

- Flooring materials

- Solvent in the manufacture of adhesives

- Polishes and carbon black

Package:

- Flexi Tank

- Drum

- ISO Tank

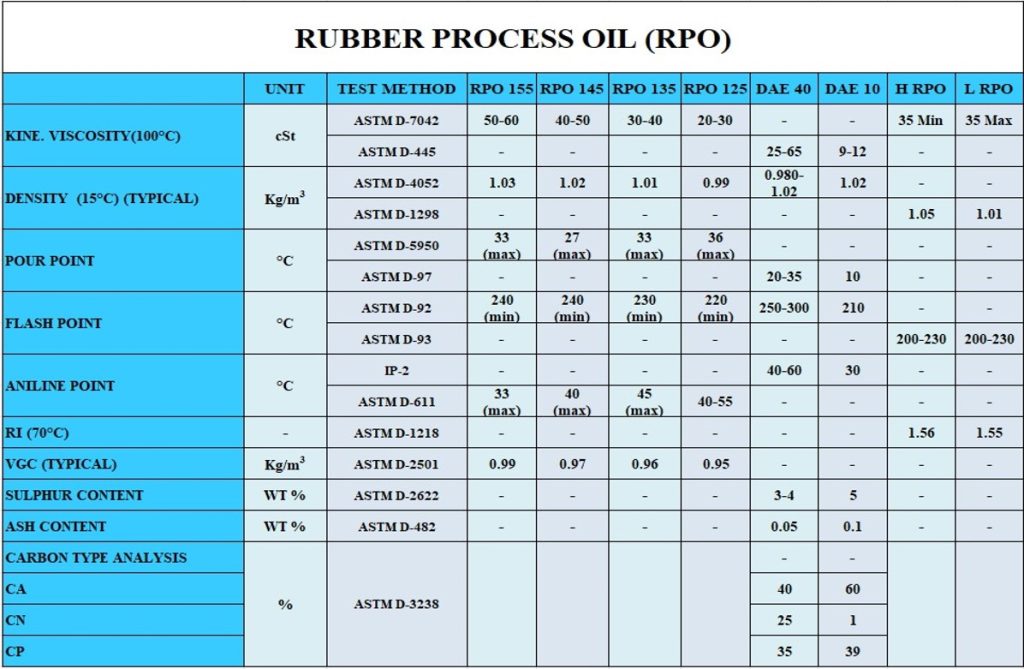

Specification