Description

Bitumen is a complex mixture of hydrocarbons, which is produced by the distillation of crude oil. The distillation process separates the various components of crude oil based on their boiling points. Bitumen is the heaviest and thickest component, which is usually left behind after the lighter components such as gasoline and diesel have been removed.

Bitumen is a highly viscous material, which means that it has a thick, sticky consistency. This property makes it ideal for use as a binder in road construction, as it helps to hold the aggregate materials together and provide a durable, waterproof surface. Bitumen can also be used as a waterproofing material in other construction applications, such as roofing and masonry.

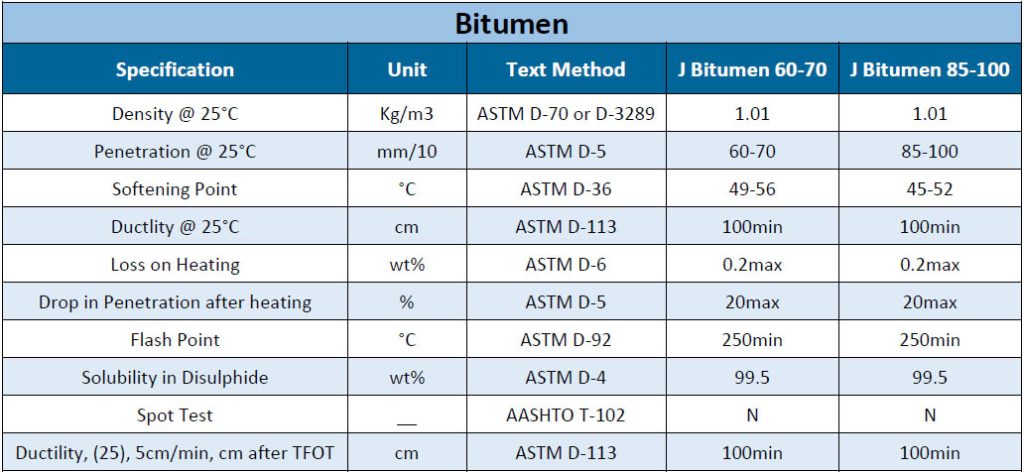

Bitumen is produced in different grades, depending on its specific properties and intended use. The most common grading system for bitumen is based on its penetration value, which is a measure of its softness or hardness. Other grading systems for bitumen include viscosity grading, performance grading, and emulsion grading.

The production and use of bitumen have environmental impacts, primarily related to the extraction and processing of crude oil. The extraction and processing of crude oil can result in air and water pollution, habitat destruction, and greenhouse gas emissions. However, efforts are being made to mitigate these impacts through the development of more sustainable practices and the use of alternative materials.

Usages

Bitumen has many applications in the construction industry, as well as in other industrial applications. Some of the most common applications of bitumen include:

- Road construction: Bitumen is widely used as a binder in the construction of roads, highways, and runways. It is mixed with aggregates to create asphalt concrete, which provides a durable, waterproof surface that can withstand heavy traffic and harsh weather conditions.

- Waterproofing: Bitumen is used in the construction of buildings and other structures to provide waterproofing and protection against moisture. It is commonly used in roofing materials, such as asphalt shingles and built-up roofing systems.

- Joint filling: Bitumen is used to fill joints and gaps in concrete structures, such as bridges and parking garages. It helps to prevent water and debris from entering the joints and causing damage.

- Adhesives and sealants: Bitumen is used as a binder in the manufacture of various types of adhesives and sealants. It provides a strong, durable bond and helps to prevent moisture and air from entering the joint.

- Pavement preservation: Bitumen is used in pavement preservation treatments, such as chip seals and fog seals. These treatments help to extend the life of the pavement by sealing cracks and preventing water from entering the pavement structure.

- Pipe coatings: Bitumen is used as a coating for pipes in the oil and gas industry. It provides corrosion protection and helps to maintain the integrity of the pipeline.

- Soundproofing: Bitumen is used as a soundproofing material in the construction of buildings and other structures. It helps to reduce noise transmission and improve acoustic performance.

- Electrical insulation: Bitumen is used as an electrical insulation material in the manufacture of electrical equipment and components. It provides a high level of insulation and helps to protect against electrical arcing and other hazards.

Overall, bitumen is a versatile material with a wide range of applications in the construction industry and other industrial applications. Its unique properties make it ideal for use in a variety of environments and applications, and ongoing research is focused on developing new and innovative uses for this valuable material

Refined Bitumen

Refined bitumen is a byproduct of crude oil. The quality of the material as well as the ease of production are greatly influenced by the source and type of crude oil used. Moreover, it’s important to note that the application of bitumen varies depending on its penetration and viscosity grade.

Different Grades:

- BITUMEN 40-50 VG 10

- BITUMEN 60-70 VG 20

- BITUMEN 80-100 VG 30

Package:

- Drum

- Jumbo Bag

Natural Bitumen

Natural Bitumen, also known as Gilsonite, is a naturally occurring substance that is found in deposits at the bottom of ancient lakes and below the Earth’s surface. Prehistoric organisms decayed and were subjected to heat and pressure, resulting in the formation of natural bitumen. These deposits are spread across the globe in different regions and can be found in various forms depending on the geological nature of the area.

Gilsonite is soluble in both aromatic and aliphatic solvents, as well as petroleum asphalt. Its unique compatibility makes it a popular choice in the construction industry, where it is used to harden softer petroleum products. Gilsonite occurs naturally in a bulk form that is shiny and black in appearance. It is brittle and can be easily crushed into a dark brown powder. The mineral is classified as a solvable material in oil solutions, such as CS2 or TCE (Trichloroethylene). It contains a high percentage of carbon and a few other elements, including nitrogen and sulfur, as well as some volatile substances.

Gilsonite is available in bulk form or as a conventional or micronized powder with various mesh sizes, depending on the customer’s needs. It has a wide range of applications, including in asphalt and road construction, insulation and roof insulation, oil well drilling fluid additives and cement, the printing ink industry, the paint industry, and the foundry industry.

In the construction industry, Gilsonite is used as a binder in asphalt and road construction. It is added to asphalt to improve its strength, durability, and resistance to wear and tear. Gilsonite is also used as a waterproofing material in roof insulation and isolation. In the oil well drilling industry, it is added to drilling fluids to improve their performance and prevent fluid loss. Gilsonite is also used as a cement additive to improve the properties of the cement, such as its strength and durability.

In the printing ink industry, Gilsonite is used as a pigment and a binder. It gives the ink a deep black color and improves its adhesion to paper. In the paint industry, it is used as a pigment and a thickener. It improves the paint’s durability and resistance to weathering and chemicals. In the foundry industry, Gilsonite is used as a mold release agent. It improves the mold’s surface finish and prevents the casting from sticking to the mold.

Gilsonite is available in jumbo bags of 1000 kg or 50 kg, depending on the customer’s needs. Its unique properties make it a valuable material in many industries, and ongoing research is focused on improving its production and reducing its environmental impact.

Sure! In addition to the applications I mentioned earlier, natural bitumen (Gilsonite) has other uses as well. Here are a few more:

1. Adhesives: Gilsonite is used as a binder in various types of adhesives, including hot melt adhesives, pressure-sensitive adhesives, and contact adhesives. It improves the adhesion properties of the adhesive and makes it more durable.

2. Inkjet printing: Gilsonite is used as a pigment and a binder in inkjet printing inks. It improves the ink’s color and stability, as well as its adhesion to the printing surface.

3. Soil stabilization: Gilsonite is used to stabilize soil in construction projects. It improves the soil’s cohesion and reduces its susceptibility to erosion.

4. Carbon black: Gilsonite is used as a feedstock in the production of carbon black, which is a common ingredient in tire manufacturing and other rubber products. It improves the quality and durability of the carbon black.

5. Friction materials: Gilsonite is used as a friction modifier in brake pads and other friction materials. It improves the material’s wear resistance and reduces noise and vibration.

6. Foundry sand additives: Gilsonite is used as a binder in foundry sand additives. It improves the sand’s strength and reduces the likelihood of casting defects.

Overall, natural bitumen (Gilsonite) has a wide range of applications in various industries, thanks to its unique properties. Its use in these industries is driven by its ability to improve the quality, durability, and performance of various products. While the production and use of natural bitumen have some environmental impacts, efforts are being made to reduce these impacts through sustainable practices and the use of alternative materials.

Package:

Jumbo Bag